Case Study – Manufacturing

Threat-led OT and IT cyber resilience for a leading U.S. manufacturing conglomerate

DOWNLOAD THE PDFAbout the client

The client is a Fortune 500 U.S. manufacturing conglomerate with more than $12B in annual revenue and 5,000+ employees. Operating across 60+ facilities, the company integrates IoT-driven smart machinery and OT systems to optimize production, but this also expands its attack surface.

The client’s challenge

The manufacturer faced rising ransomware threats targeting IoT and OT systems, limited visibility across siloed IT/OT environments, and exposure from legacy assets, third-party vendors, and decentralized systems. They needed to align detection and response with operational use cases while closing blind spots across their factories and supply chain.

Benefits

- Faster detection and response: The manufacturer reduced mean time to detect (MTTD) by 23% and mean time to respond (MTTR) by 29%, accelerating containment of threats before business disruption could occur.

- Unified IT/OT visibility: The CyberProof-Armis integration closed visibility gaps by unifying IT, OT, and IoT monitoring across 60 facilities and more than 5,000 endpoints.

- CTEM implementation: A Continuous Threat Exposure Management program prioritized risks, validated defenses, and aligned detections to adversary techniques targeting manufacturing systems.

- Regulatory confidence: The organization used CyberProof dashboards tailored to manufacturing compliance standards such as IEC 62443 and the NIST Cybersecurity Framework.

Our solution

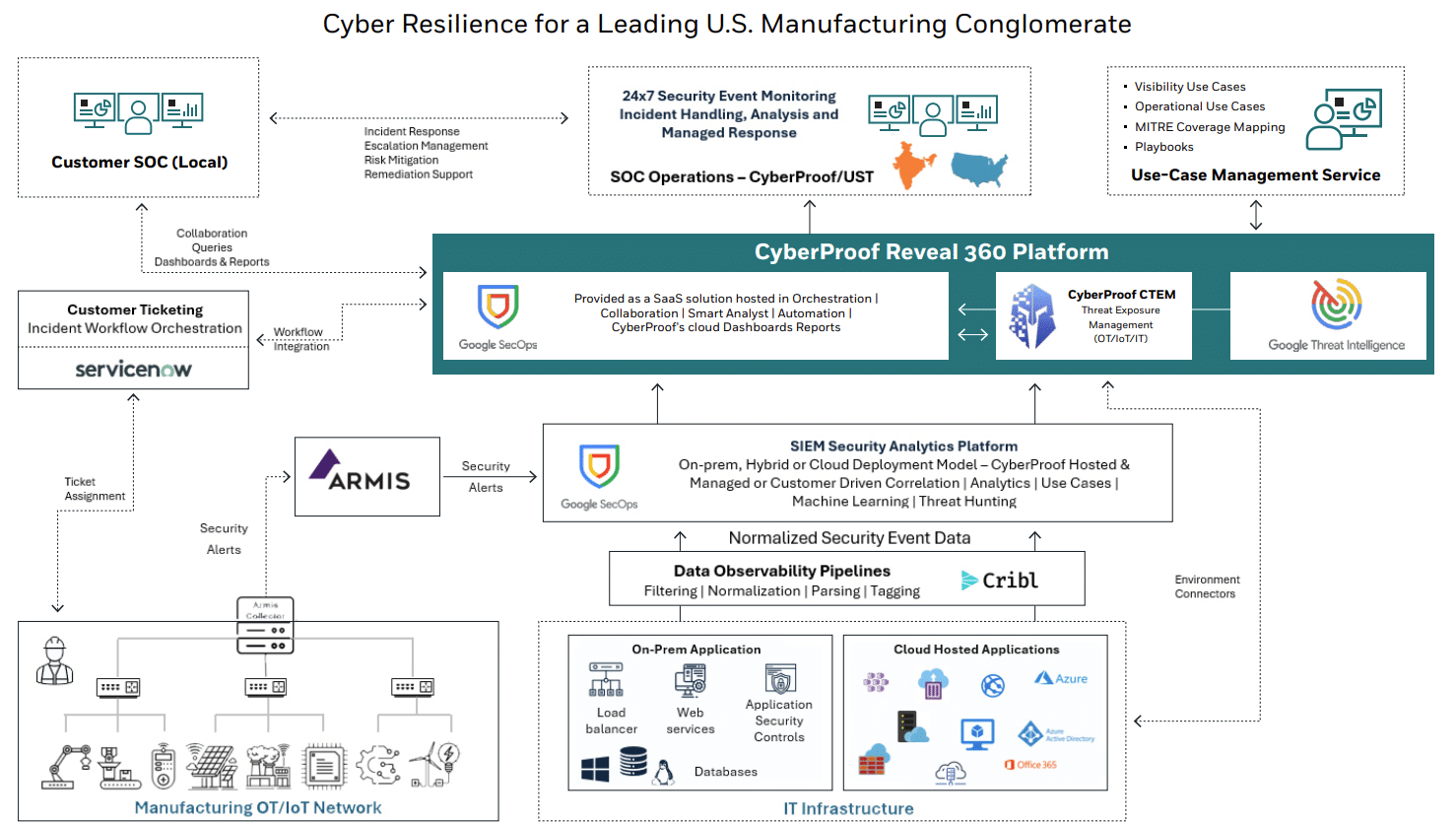

CyberProof delivered an integrated cyber defense strategy combining:

- 24×7 MDR services using the CDC Reveal360 platform to monitor IT, OT, and cloud environments. Services were provided from CyberProof’s Ohio SOC during business hours and from the Trivandrum, India SOC outside of business hours.

- OT/IoT visibility via integration with Armis for passive monitoring of smart factory assets. This integration allowed the CyberProof platform to ingest Armis telemetry and correlate it with threat intelligence, alerting, and incident management pipelines.

- Threat Exposure Management (CTEM) to continuously assess and prioritize risks, aligned to MITRE ATT&CK.

- Use Case Management to build tailored detections and playbooks, including OT-specific scenarios such as PLC configuration changes. For example – the Visibility Use Case: Monitoring unauthorized device behavior in OT networks.

- Threat intelligence enrichment through Google Threat Intelligence (Mandiant), mapping industrial threats to MITRE coverage.

Results

The client achieved full-spectrum IT/OT visibility, faster detection and response (MTTD reduced by 23%, MTTR by 29%), and tailored compliance to manufacturing standards like IEC 62443 and NIST CSF. Today, the manufacturer operates with greater resilience and confidence through continuous exposure management and proactive threat coverage.

Speak with an expert

Explore how CyberProof can help you anticipate, prevent, and mitigate ever-evolving cyberattacks in hybrid IT/OT/IoT and cloud-native environments.